High velocity fans are powerful tools for improving air circulation and maintaining comfortable temperatures in a wide range of settings. A high velocity fan is defined by its ability to move air at high speeds. Unlike traditional fans that typically operate at slower speeds and are designed to provide gentle air circulation, high velocity fans are specifically designed to move large volumes of air at high speeds, creating a strong breeze that can cool down large spaces quickly and efficiently. Read More…

Since 1991, National Turbine Corporation has been a blower manufacturer, bringing you quality multi stage blowers for use in industrial applications.

#1 Most Reliable Fan Manufacturer. Thousands of customers depend on AirPro fans to keep their operations going, and that's why we build the highest quality fans, prioritize on-time delivery, and offer a 3-year warranty on all products! Founded in 2002, AirPro is privately held and 100% Employee-Owned. With headquarters and manufacturing facilities in Rhinelander, Wisconsin, we offer centrifugal...

Since 1889, The New York Blower Company (nyb) has been a turn-key provider of catalog and custom fans, blowers and ventilation systems. We provide the design, manufacture, installation, maintenance, repair and rebuild of nyb and competitor products. We are constantly expanding, with a worldwide presence of over 200 representatives, and the opening of our fifth manufacturing facility in the US in ...

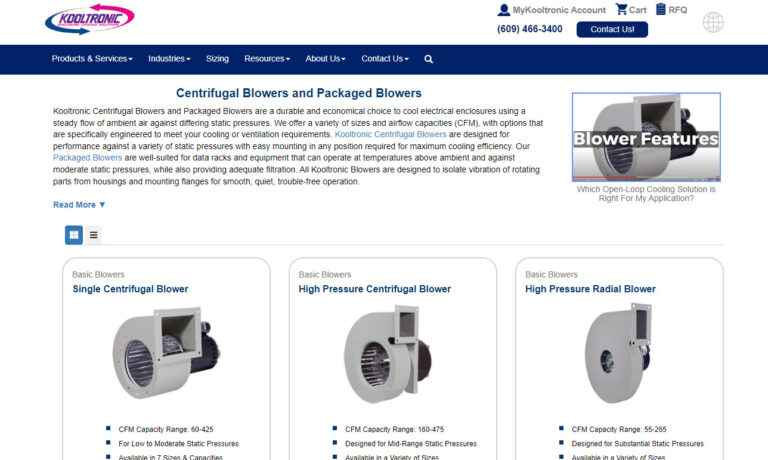

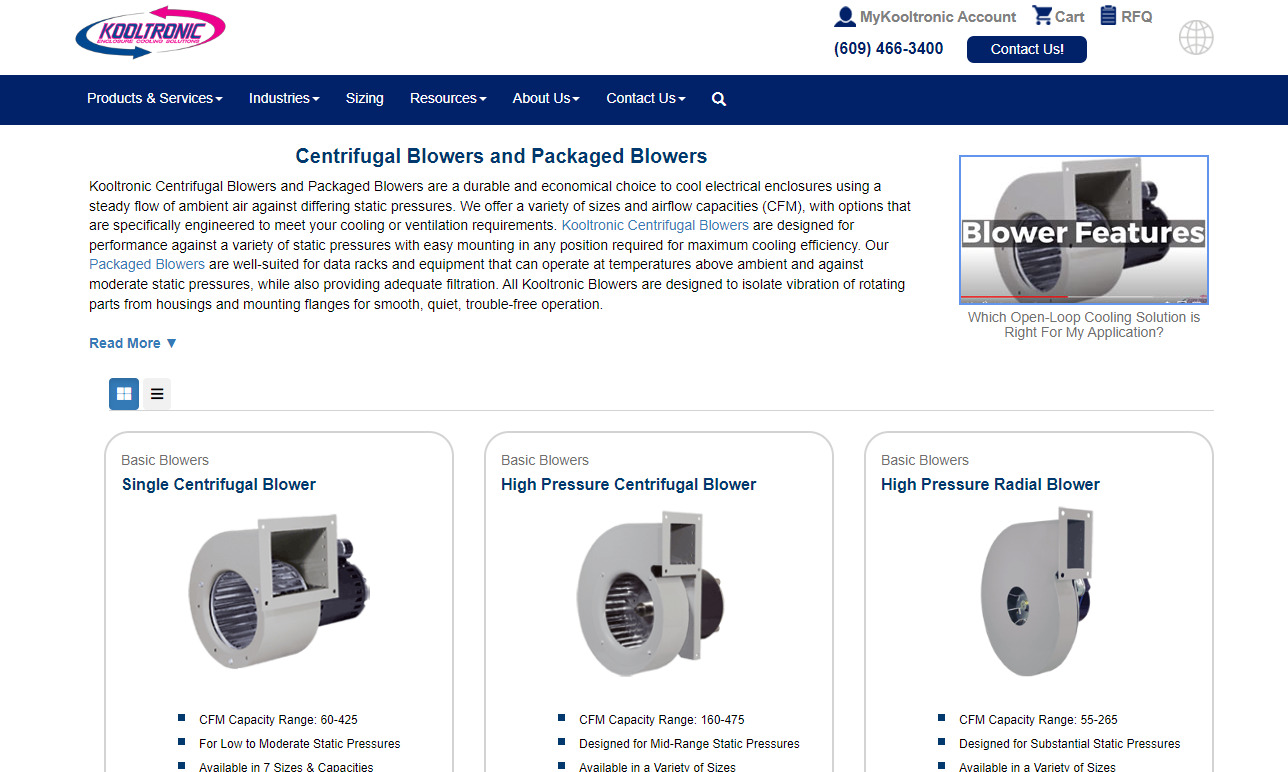

At Kooltronic, we have established ourselves as a leading manufacturer specializing in a comprehensive array of blowers tailored to meet various industrial requirements. Our expansive product line encompasses high-pressure air blowers, centrifugal blowers, impeller blowers, and high-pressure radial blowers, showcasing our proficiency and versatility in the field.

Republic Manufacturing offers industries a wide array of air moving solutions. Currently, our product range includes blowers, vacuum pumps, compressors, air knives, motors, and systems. While many products are available for immediate shipment, Republic's in-house staff of engineers can design custom options to meet specifications necessary utilizing state-of-the-art software and machinery. We...

If you are looking for a solution solving industrial blower supplier, look to Hartzell Air Movement. We have been an industrial blower manufacturer for 75 years & carry products such as air blowers, exhaust fans, industrial fans, centrifugal blowers & high velocity fans for the air moving community. At Hartzell, our mission is to provide high quality & reliable industrial air moving equipment &...

More High Velocity Fan Manufacturers

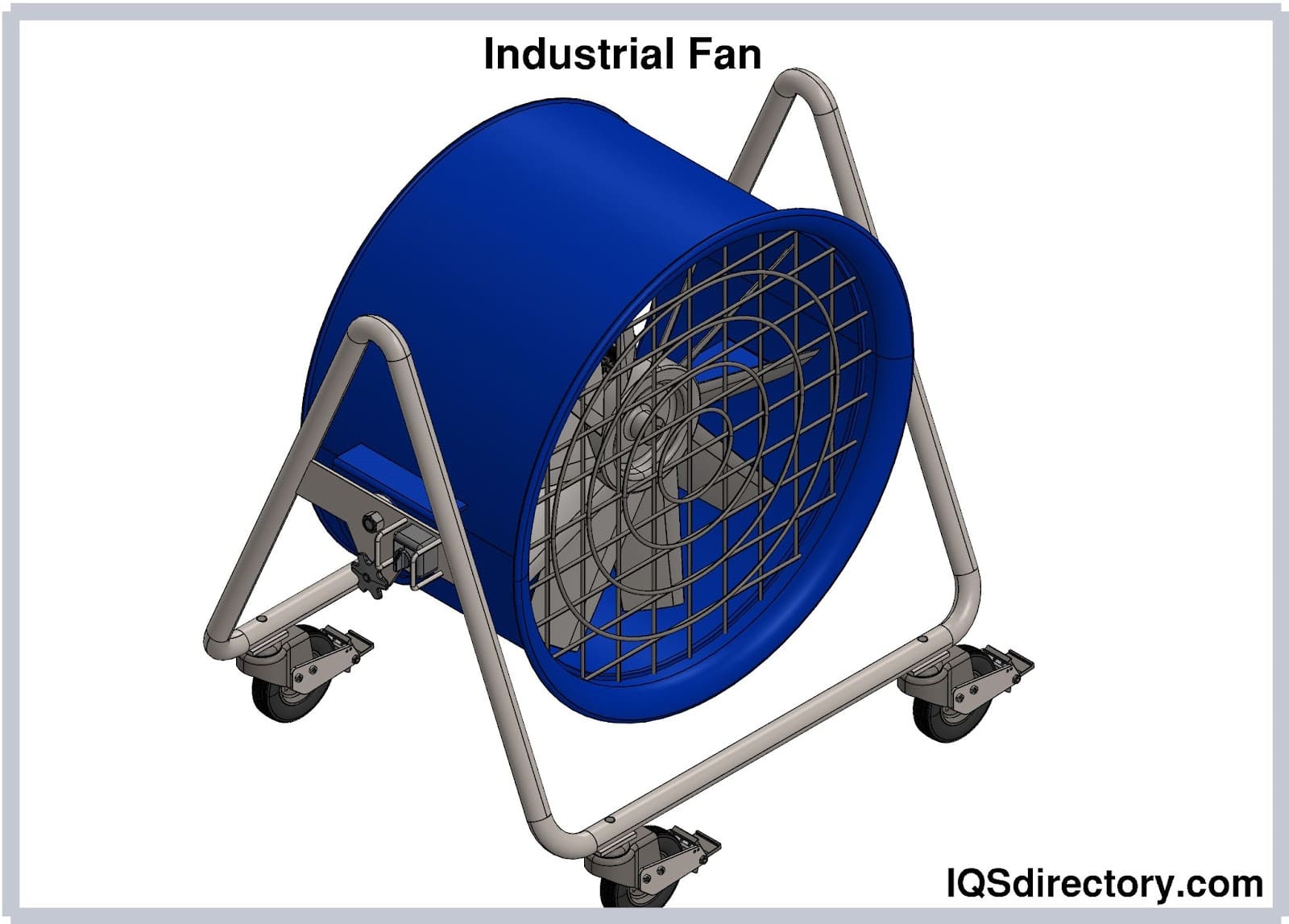

Components of High Velocity Fans

High velocity fans come in various shapes and sizes, but all feature several key components that allow them to function effectively. A high velocity fan has a motor that powers the blades, which are designed to move air at high speeds. The grille on the front of the fan protects the blades and also directs air flow in specific directions. Oscillation mechanisms enable the fan to rotate, covering a wider area. Speed control is a feature that allows users to adjust the speed of the fan according to their preferences. Remote control and timer functions offer additional convenience and flexibility.

Types of High Velocity Fans

There are several types of high velocity fans available, each with specific applications. For example,

Floor Fans

Floor fans are the most common type and are typically used in large open spaces such as warehouses or industrial settings. They are also a popular choice for residential homes as they can be easily moved from room to room and are often more affordable than other types of high velocity fans.

Wall-Mounted Fans

Wall-mounted fans are fixed to a wall and are ideal for smaller spaces such as rooms in residential homes, offices, or commercial buildings. They are often used to target specific areas or to provide ventilation in rooms with poor air circulation.

Pedestal Fans

Pedestal fans are supported by a stand and can be adjusted to various heights. They are typically used in larger rooms or open spaces and can provide targeted air flow in a particular direction. Pedestal fans are also popular for outdoor events such as weddings or concerts, where they can provide ventilation and cooling for large crowds.

Ceiling Fans

Ceiling fans are installed on the ceiling and are ideal for cooling entire rooms. They are popular in residential homes as they can reduce the need for air conditioning and help lower energy costs. Ceiling fans are also often used in commercial buildings such as offices or restaurants, where they can improve air circulation and provide additional comfort for customers or employees.

Considerations Regarding High Velocity Fans

High velocity fans do have some considerations to account for. Noise is a common issue, especially at higher speeds. Power consumption can also be a concern, particularly with larger or more powerful models. Safety is another consideration, as high-speed blades can cause injury if they come into contact with people or objects.

Benefits of High Velocity Fans

Despite these considerations, high velocity fans offer many benefits. Improved air circulation is one of the most significant advantages, as they can move air through large spaces quickly and efficiently. They are also energy-efficient and can help reduce energy bills compared to traditional air conditioning systems. Cost-effectiveness is another benefit, as high velocity fans are often cheaper to purchase and maintain than other cooling systems. Finally, high velocity fans are versatile and can be used in a wide range of settings, making them an excellent choice for both residential and commercial spaces.

Applications of High Velocity Fans

High velocity fans are used in many different settings, including:

Industrial Settings

In industrial settings, high velocity fans are used to cool down machinery and improve air quality.

Warehouses and Storage Facilities

High velocity fans are used in warehouses and storage facilities to regulate temperatures and improve air circulation.

Gyms and Fitness Centers

High velocity fans are used in gyms and fitness centers to keep customers cool and prevent overheating during workouts.

Outdoor Events

At outdoor events, high velocity fans are used to cool down large crowds or provide ventilation in enclosed areas.

Kitchens and Restaurants

High velocity fans are used in kitchens and restaurants to remove steam and smoke and prevent the buildup of hot air.

Offices and Commercial Buildings

In offices and commercial buildings, high velocity fans are used to regulate temperatures and improve air quality.

Residential Homes

High velocity fans are used in residential homes to improve air circulation and reduce the need for air conditioning.

Choosing the Proper High Velocity Fan Supplier

To ensure you have the most productive outcome when purchasing a high velocity fan from a high velocity fan supplier, it is important to compare several companies using our directory of high velocity fan suppliers. Each high velocity fan supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or to request a quote. Review each high velocity fan business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple high velocity fan companies with the same form.

Air Compressors

Air Compressors  Air Filters

Air Filters Air Pollution Control

Air Pollution Control Blowers

Blowers Dust Collectors

Dust Collectors Industrial Vacuum Cleaning Equipment

Industrial Vacuum Cleaning Equipment Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services