Axial fans are a type of fan that have been used for decades to provide cooling and ventilation in various industries and applications. They work by creating airflow in a straight line, parallel to the fan’s axis of rotation. Read More…

Since 1991, National Turbine Corporation has been a blower manufacturer, bringing you quality multi stage blowers for use in industrial applications.

#1 Most Reliable Fan Manufacturer. Thousands of customers depend on AirPro fans to keep their operations going, and that's why we build the highest quality fans, prioritize on-time delivery, and offer a 3-year warranty on all products! Founded in 2002, AirPro is privately held and 100% Employee-Owned. With headquarters and manufacturing facilities in Rhinelander, Wisconsin, we offer centrifugal...

Since 1889, The New York Blower Company (nyb) has been a turn-key provider of catalog and custom fans, blowers and ventilation systems. We provide the design, manufacture, installation, maintenance, repair and rebuild of nyb and competitor products. We are constantly expanding, with a worldwide presence of over 200 representatives, and the opening of our fifth manufacturing facility in the US in ...

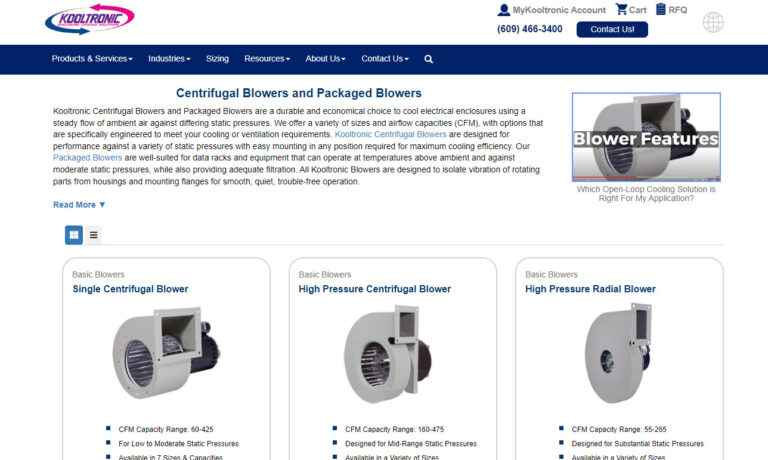

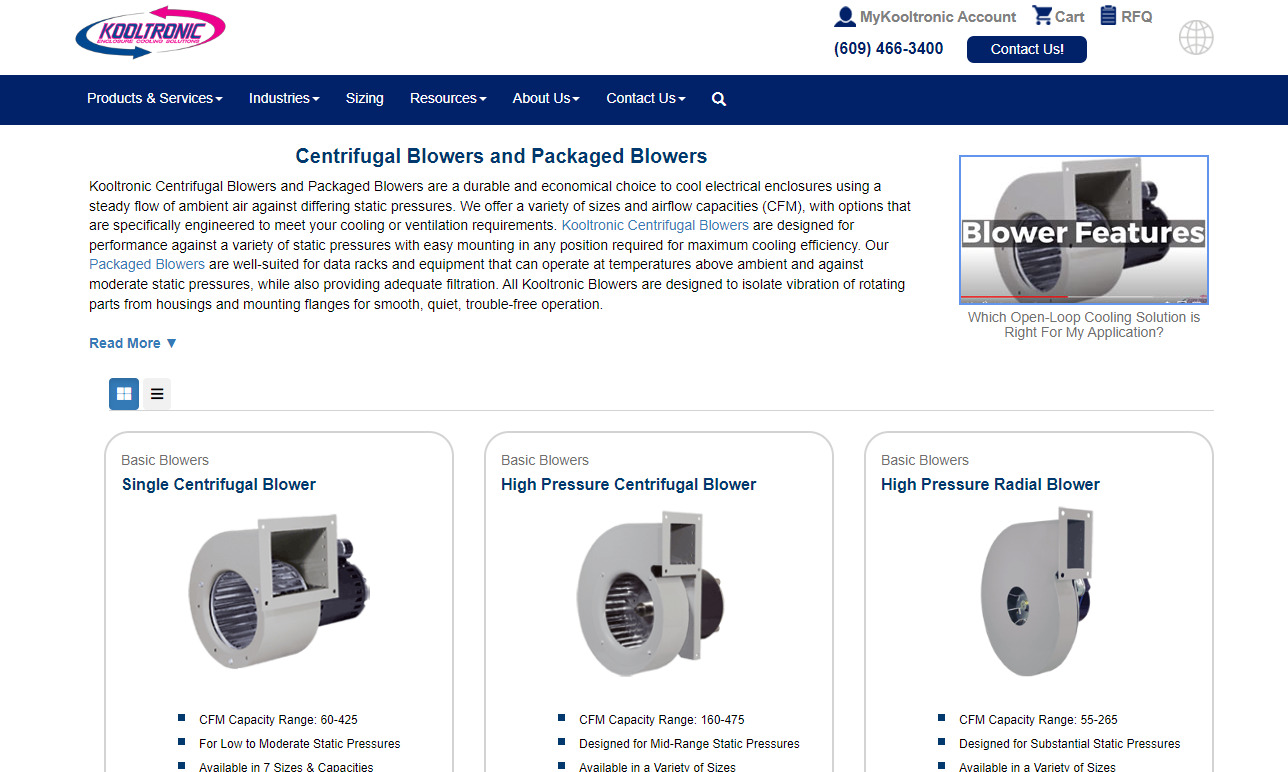

At Kooltronic, we have established ourselves as a leading manufacturer specializing in a comprehensive array of blowers tailored to meet various industrial requirements. Our expansive product line encompasses high-pressure air blowers, centrifugal blowers, impeller blowers, and high-pressure radial blowers, showcasing our proficiency and versatility in the field.

Republic Manufacturing offers industries a wide array of air moving solutions. Currently, our product range includes blowers, vacuum pumps, compressors, air knives, motors, and systems. While many products are available for immediate shipment, Republic's in-house staff of engineers can design custom options to meet specifications necessary utilizing state-of-the-art software and machinery. We...

If you are looking for a solution solving industrial blower supplier, look to Hartzell Air Movement. We have been an industrial blower manufacturer for 75 years & carry products such as air blowers, exhaust fans, industrial fans, centrifugal blowers & high velocity fans for the air moving community. At Hartzell, our mission is to provide high quality & reliable industrial air moving equipment &...

More Axial Fan Manufacturers

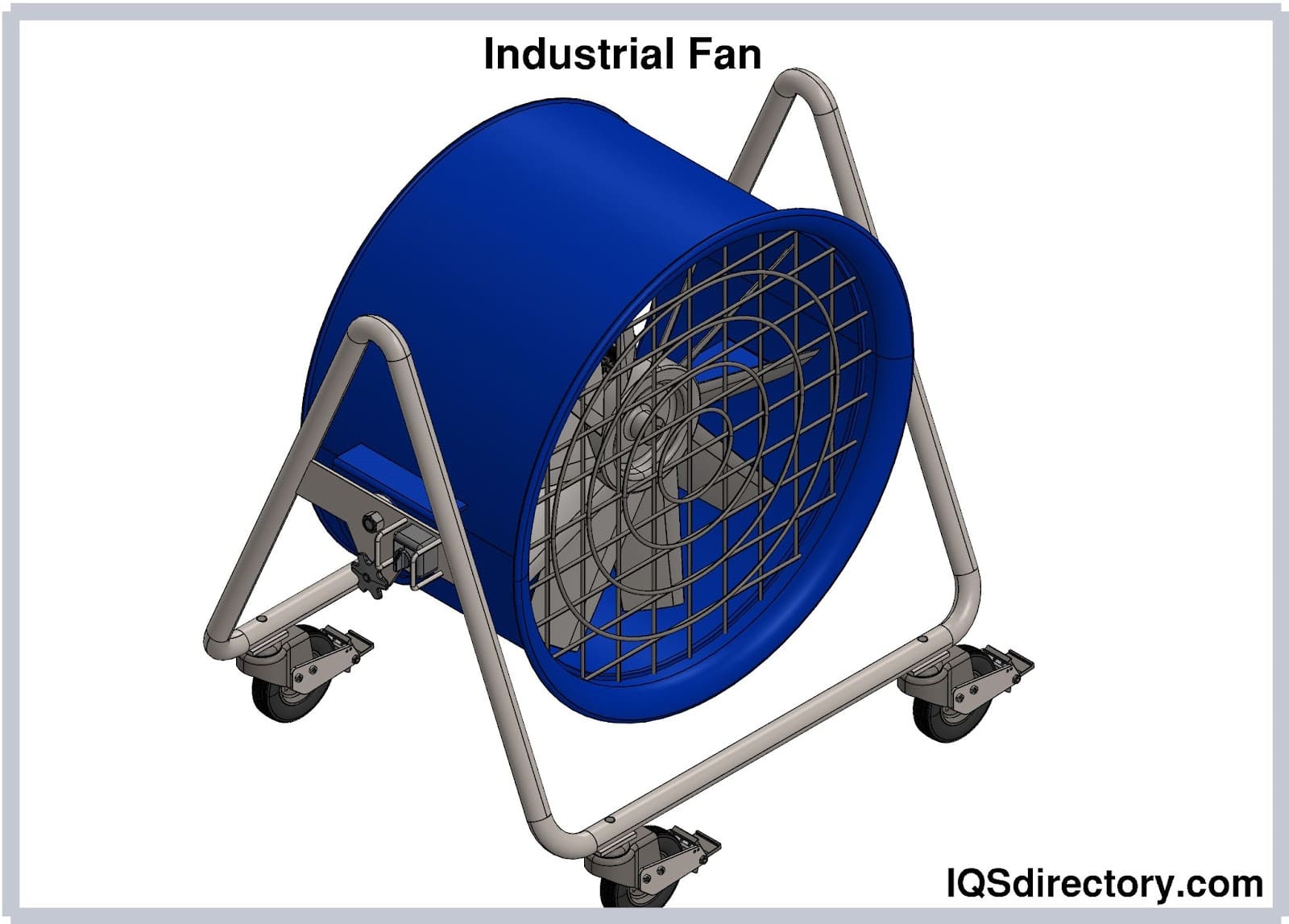

Components of Axial Fans

Axial fans are made up of four main components: blades or impellers, a hub, a motor or power source, and a guard or housing. The blades or impellers are the most critical part of the fan as they are responsible for creating airflow. The hub is the center of the fan, and the blades are attached to it. The motor or power source provides the energy required to rotate the blades, and the guard or housing prevents injury and damage to the fan and surroundings.

When these components work together, they create airflow in a straight line, making axial fans an ideal choice for applications requiring high-volume, low-pressure airflow. The basic working principle of axial fans is that the motor rotates the blades, creating airflow in a straight line. The guard or housing ensures that the airflow is focused and directed, while also providing protection to the blades and the surroundings.

Design Variations of Axial Fans

Axial fans come in various designs that cater to specific applications. Adjustable pitch blades are a design variation that allows the blades' angle to be adjusted, allowing for optimal airflow in various applications. Variable speed motors are another design variation that allows for the fan's speed to be adjusted to cater to different airflow requirements. Ducted or non-ducted designs are variations that refer to whether the fan is enclosed in a duct or not. Fan diameter and blade count are design variations that cater to specific airflow requirements. Different mounting configurations are also available to cater to various installation requirements, such as ceiling or wall-mounted fans.

Materials Used in Axial Fans

Axial fans can be made from various materials, such as aluminum, steel, plastic, and composite materials. The choice of material depends on various factors, such as the environment in which the fan will be used, the airflow requirements, and the cost. Aluminum is a popular choice for its lightweight and corrosion-resistant properties. Steel is used when high-strength and durability are required, while plastic is a cost-effective option for low airflow applications. Composite materials offer a balance between strength and weight, making them ideal for aviation and aerospace applications.

Considerations Regarding Axial Fans

Despite their versatility and adaptability, axial fans have some considerations that must be taken into account when choosing them for specific applications. The noise level can be a limitation, especially in quiet environments, and pressure limitations may restrict the airflow rate in high-pressure applications. The efficiency of the fan can also be a limitation, with some designs being less efficient than others. Maintenance and servicing requirements must be considered, and appropriate use and installation are essential to ensure safety and optimal performance.

However, these considerations must be examined only in comparison to other types of fans for specific applications which may favor another option. While these factors may present some limitations, they are not necessarily drawbacks of axial fans as a whole, and there are often design variations and strategies that can be employed to mitigate these limitations. For example, while axial fans may produce higher noise levels compared to other types of fans, they are still designed to operate at relatively low noise levels compared to other types of equipment. Similarly, while axial fans may be less efficient than some other types of fans (such as centrifugal fans), they are often more efficient than other types of equipment used for similar applications. As a result, weighing both the benefits and considerations regarding axial fans as a whole versus the specific benefits provided by other types of fans may be unfair.

Benefits of Axial Fans

So, after hopefully sorting out any potential conflicting information, axial fans offer several benefits as a whole over other equipment, including:

High Airflow Rate and Efficiency

These are among the primary benefits of axial fans. They consume less energy than other types of fans, making them cost-effective and environmentally friendly.

Low Noise Levels

Axial fans are designed to operate at lower noise levels compared to other types of fans, making them ideal for use in residential and commercial buildings, as well as other noise-sensitive environments.

Easy Maintenance

Axial fans are easy to maintain, with simple components that are easy to replace. This can help reduce downtime and maintenance costs.

Compact Size

Axial fans are generally smaller and more compact than other types of fans, making them ideal for use in applications where space is limited.

High Durability

Axial fans are made from durable materials that are able to withstand harsh environmental conditions, making them suitable for use in a wide range of applications.

High Adaptability

Axial fans can be customized to meet specific requirements, such as the need for variable speed control, the ability to operate in extreme temperatures or harsh environments, and the need for corrosion-resistant materials.

High Reliability

Axial fans are known for their reliability and long lifespan, making them an ideal choice for applications where continuous operation is required.

High Versatility

Versatility and adaptability are also benefits of axial fans, as they can be used in various applications.

Applications of Axial Fans

As a result of these benefits, axial fans are used in various applications, including:

Cooling and Ventilation in Buildings

Axial fans are used in HVAC (Heating, Ventilation, and Air Conditioning) systems to circulate air and maintain comfortable indoor temperatures.

Air Conditioning Systems

Axial fans are used in air conditioning units to circulate air and remove heat.

Industrial Processes

Axial fans are used in industrial processes such as chemical processing, pharmaceuticals, food processing, and manufacturing to regulate temperature, circulate air, and remove fumes.

Agriculture and Farming

Axial fans are used in poultry farms and greenhouses to provide ventilation and maintain optimal temperatures for plant growth and animal health.

Automotive and Transportation

Axial fans are used in cars and trucks to cool engines and radiators.

Aerospace and Aviation

Axial fans are used in aircraft engines to provide cooling and ventilation.

Power Generation

Axial fans are used in power plants to cool generators and turbines.

Mining and Excavation

Axial fans are used in mines and tunnels to provide ventilation and remove harmful fumes.

Marine and Offshore

Axial fans are used in ships and offshore platforms to provide ventilation and maintain air quality.

Choosing the Proper Axial Fan Supplier

To ensure you have the most productive outcome when purchasing an axial fan from an axial fan supplier, it is important to compare several companies using our directory of axial fan suppliers. Each axial fan supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or to request a quote. Review each axial fan supplier using our proprietary website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple axial fan companies with the same form.

Air Compressors

Air Compressors  Air Filters

Air Filters Air Pollution Control

Air Pollution Control Blowers

Blowers Dust Collectors

Dust Collectors Industrial Vacuum Cleaning Equipment

Industrial Vacuum Cleaning Equipment Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services