An exhaust fan is a type of fan that is used to ventilate out moisture, unwelcome aromas, smoke, particles, and other air impurities in order to regulate the environment inside a building. A heating and cooling system may also include exhaust fans. Exhaust fans are frequently seen in bathrooms and kitchens, but they can also be found in a wide variety of other places requiring ventilation because they are extremely simple to install in most situations. Read More…

Since 1991, National Turbine Corporation has been a blower manufacturer, bringing you quality multi stage blowers for use in industrial applications.

#1 Most Reliable Fan Manufacturer. Thousands of customers depend on AirPro fans to keep their operations going, and that's why we build the highest quality fans, prioritize on-time delivery, and offer a 3-year warranty on all products! Founded in 2002, AirPro is privately held and 100% Employee-Owned. With headquarters and manufacturing facilities in Rhinelander, Wisconsin, we offer centrifugal...

Since 1889, The New York Blower Company (nyb) has been a turn-key provider of catalog and custom fans, blowers and ventilation systems. We provide the design, manufacture, installation, maintenance, repair and rebuild of nyb and competitor products. We are constantly expanding, with a worldwide presence of over 200 representatives, and the opening of our fifth manufacturing facility in the US in ...

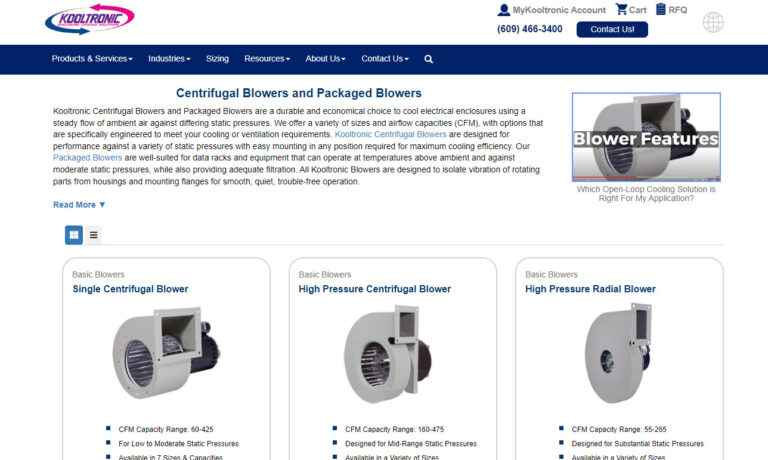

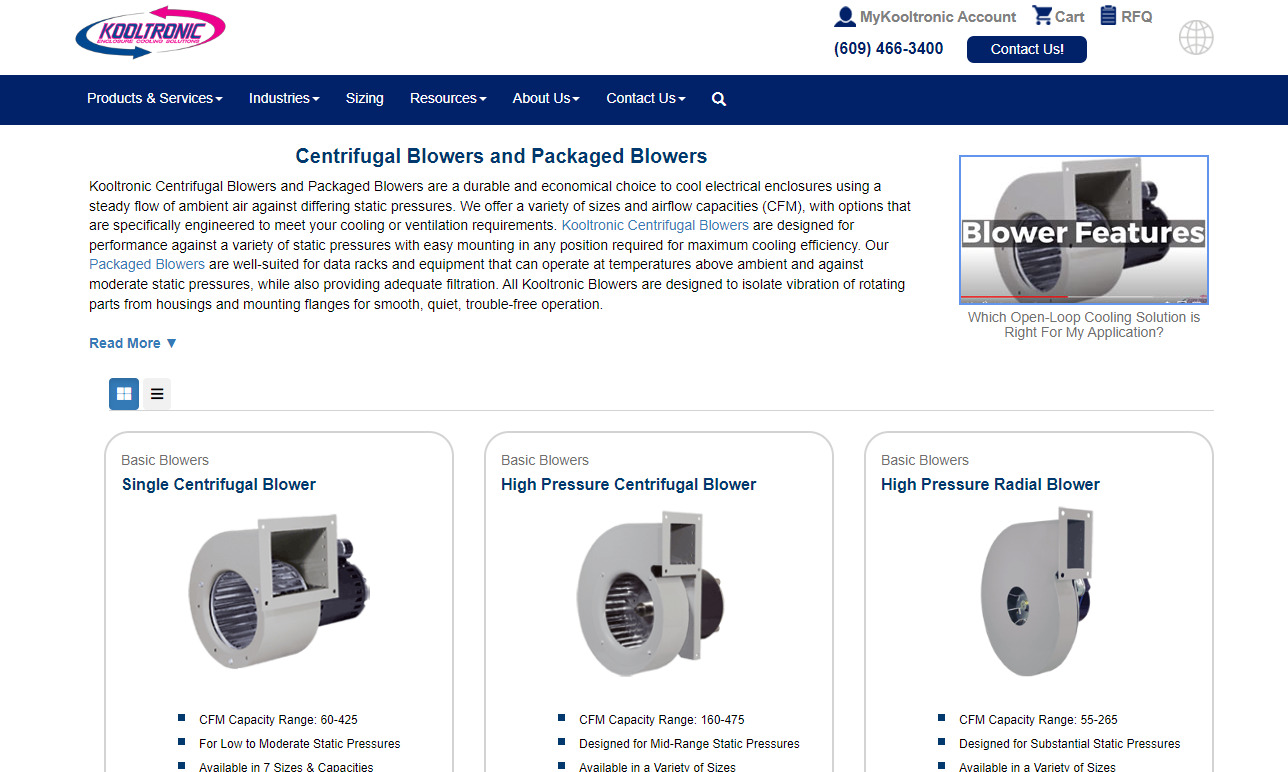

At Kooltronic, we have established ourselves as a leading manufacturer specializing in a comprehensive array of blowers tailored to meet various industrial requirements. Our expansive product line encompasses high-pressure air blowers, centrifugal blowers, impeller blowers, and high-pressure radial blowers, showcasing our proficiency and versatility in the field.

Republic Manufacturing offers industries a wide array of air moving solutions. Currently, our product range includes blowers, vacuum pumps, compressors, air knives, motors, and systems. While many products are available for immediate shipment, Republic's in-house staff of engineers can design custom options to meet specifications necessary utilizing state-of-the-art software and machinery. We...

If you are looking for a solution solving industrial blower supplier, look to Hartzell Air Movement. We have been an industrial blower manufacturer for 75 years & carry products such as air blowers, exhaust fans, industrial fans, centrifugal blowers & high velocity fans for the air moving community. At Hartzell, our mission is to provide high quality & reliable industrial air moving equipment &...

More Exhaust Fans Manufacturers

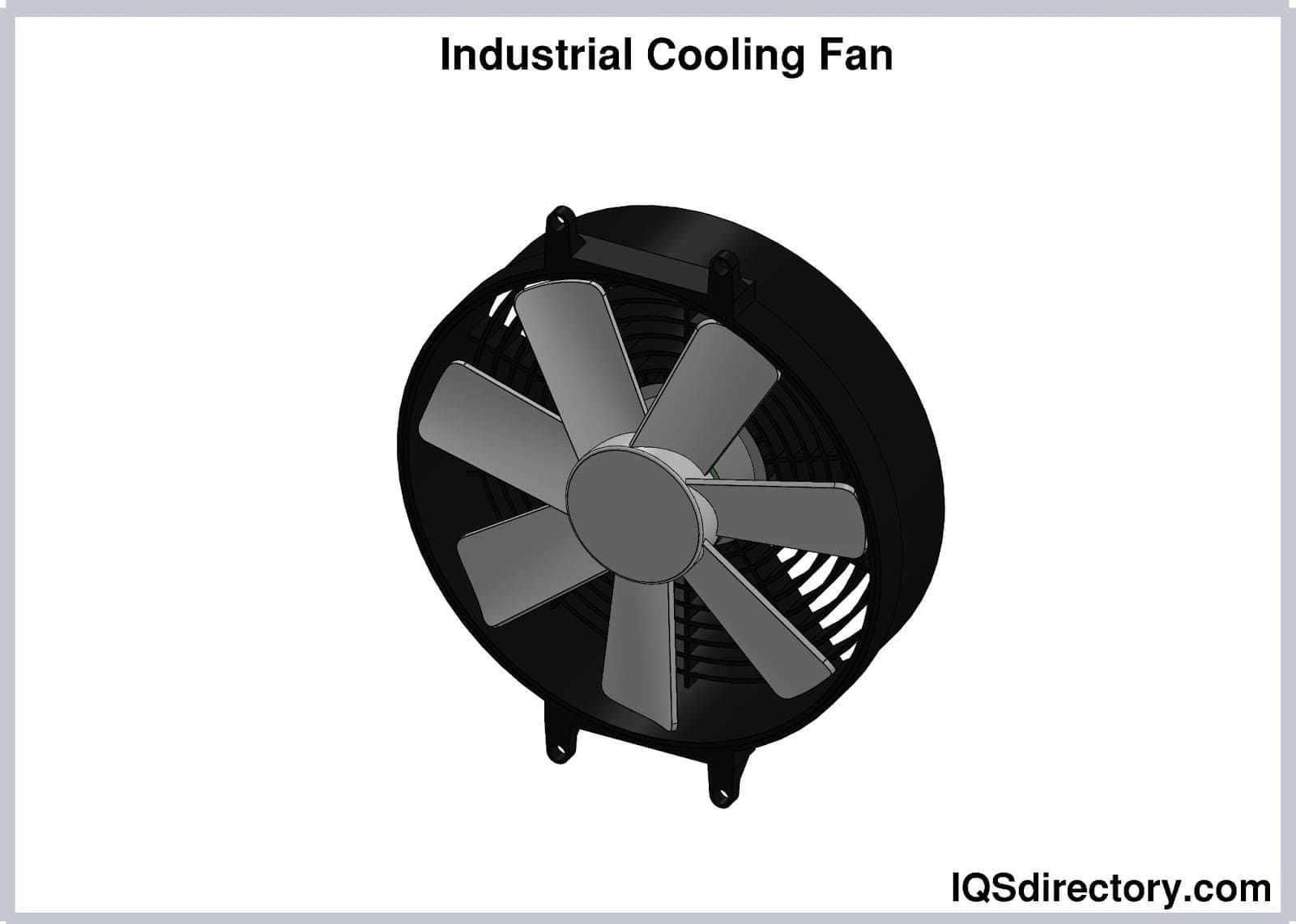

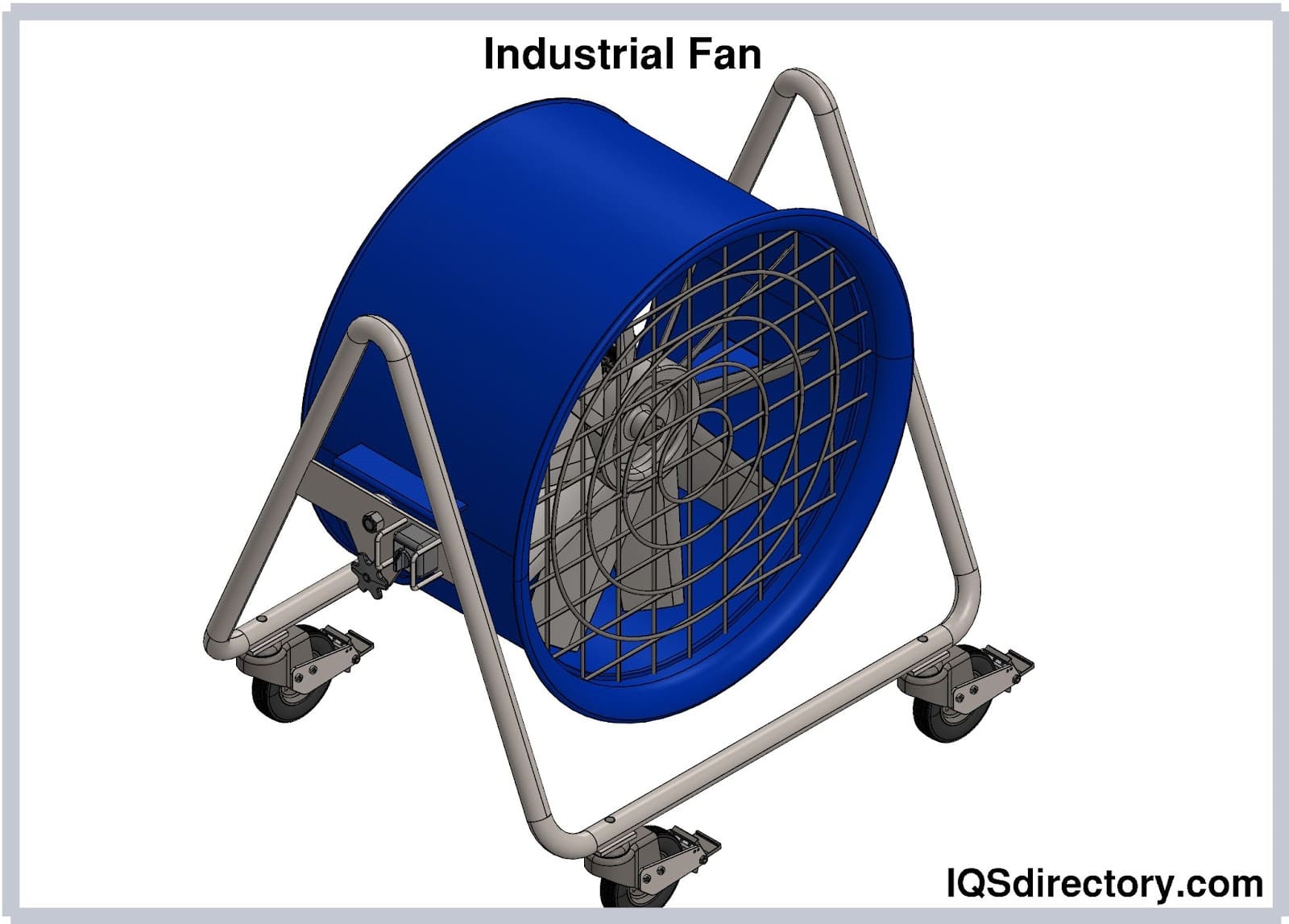

How Exhaust Fans Work

Exhaust fans function by drawing hot or humid air out of a condensed, compact space while enabling fresh air to enter from another location (perhaps a doorway or vent) to replace it. A ducting system is used to transport the undesirable air that has been extracted by an exhaust fan outside. The fan's blades, which are used to remove air from the room, are turned by a motor. Electricity is used to run exhaust fans. Wall switches can be used to operate them, and some versions come with sensors that tell the appliance to turn on or off when a particular level of air quality (typically humidity) is reached nearby.

Types of Exhaust Fans

Wall Exhaust Fan

The most popular type of exhaust fan in residences is a wall-mounted model, particularly in those areas with walls that face an open space. Installing this kind of exhaust fan is straightforward and may be done with little difficulty. This type of exhaust fan is efficient in removing stale and unclean air from houses. Additionally, no special exhaust ducts or Mechanical Ventilation with Heat Recovery (MVHR) system parts are necessary for this kind of exhaust fan. Wall-mounted exhaust fans are typically acceptable for installation not only in the bedroom or living room, but also in the kitchen or restroom.

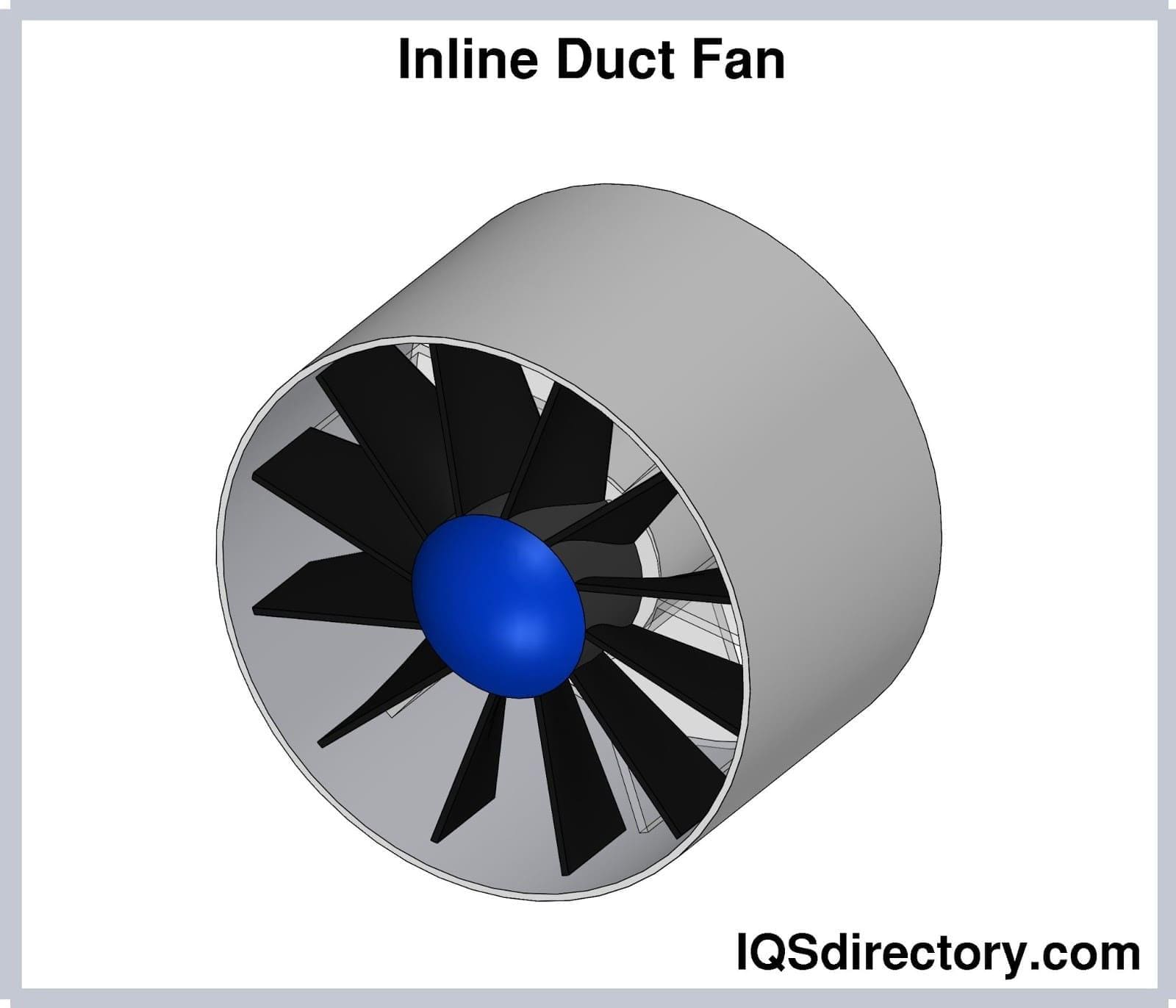

Inline Exhaust Fans

Inline exhaust fans are frequently the best option for rooms that lack adequate ventilation. They are mounted in-between a building’s ductwork and aid in the removal of stale air from the ducts. Powerful blower fans, inline exhaust fans can move a lot of air. However, compared to other fans, these use less energy. Heat and moisture can be removed from a big room using inline exhaust fans. To prevent overheating, AV (audio-visual) equipment and hosting server cabinet systems should both be paired with inline exhaust fans since they are created, in essence, to cool and ventilate big spaces. Inline exhaust fans frequently come with flexible duct tubes and add-ons like carbon filters and silencers, which increases their adaptability but lessens their efficiency.

Ceiling-Mounted Exhaust Fan

In order to avoid having to direct unclean air through an exhaust duct, a ceiling-mounted exhaust fan is typically put in a space that is not adjacent to an open area. An air-exhaust duct system known as Mechanical Ventilation Heat Recovery (MVHR) is necessary for this kind of exhaust fan. This system, which distributes air to the outside of the home, employs a duct mounted on the ceiling or within the ceiling. Typically, ceiling exhaust fans are 8 inches, 10 inches, or 12 inches in size. The size of the fan chosen must take into consideration the size of the room and the ventilation ducts utilized.

Window Exhaust Fan

Window exhaust fans have side panels that may be expanded to encompass an entire window opening and are designed to fit snugly against an open window. Common configurations for window exhaust fan units consist of a single large fan or two smaller fans installed side by side are. Most window exhaust fans have two or three settings that can be adjusted (low, medium, and fast), and some of them can be turned around to operate in either the in or out position.

Some fans feature a thermostat that will shut themselves off if the temperature falls below a set level, or they have a grille that can be moved to control the airflow. Other fans have sophisticated technological functions like a timer and remote control.

Benefits of Exhaust Fans

- When a space becomes too warm after using the shower or cooking, exhaust fans can swiftly cool that area down. Without activating an entire, and expensive, air conditioning system, hot air is vented outside to bring down the temperature.

- Humidity control is a crucial component of any well-functioning bathroom. Extreme humidity puts the bathroom walls and ceiling at risk for damage, peeling paint, and the growth of molds, viruses, and bacteria. Mold can grow to be a major worry, particularly for young people and the elderly. One of the main benefits of an exhaust fan is that it can help in the reduction of mold and other harmful agents from building up and becoming more difficult and expensive to remove later by other means. Not only do these devices help clear the air of any spore accumulation, they additionally aid in reducing the pace of mold formation by decreasing humidity.

- Exhaust fans enhance the quality of indoor air through the removal of impurities, smells, and humidity. They offer sufficient ventilation for spaces where fouling odors may accumulate. In order to let freshly-conditioned air fill a room, these fans vent stagnant air out of the spaces where such odors would otherwise accumulate.

- Additionally, harsh chemicals are frequently employed to clean areas, and these chemicals can be harmful to human health if inhaled. Exhaust fans help to quickly remove these agents from spaces requiring their use.

Choosing the Correct Exhaust Fans Supplier

To make sure you have the most constructive outcome when purchasing Exhaust Fans from an Exhaust Fans Manufacturer, it is important to compare at least 4 or 5 Suppliers using our list of Exhaust Fans manufacturers. Each Exhaust Fans Supplier has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Exhaust Fans business website using our proprietary website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple Exhaust Fans companies with the same form.

Air Compressors

Air Compressors  Air Filters

Air Filters Air Pollution Control

Air Pollution Control Blowers

Blowers Dust Collectors

Dust Collectors Industrial Vacuum Cleaning Equipment

Industrial Vacuum Cleaning Equipment Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services